Steel braided hoses play a vital role in systems where durability, flexibility, and resistance to extreme conditions are required. These reinforced hoses combine an inner flexible core, often rubber or PTFE, with an outer layer of stainless steel braid, offering excellent strength without compromising flexibility. Their use spans across various sectors, including aerospace, automotive, industrial, and marine environments.

In this article, we will explore seven of the most common applications for steel braided hoses, highlighting why they are chosen for demanding tasks and how they ensure system reliability and performance.

1. Aerospace Hydraulic and Fuel Systems

In the aerospace industry, performance and safety are non-negotiable. Steel braided hoses are extensively used in hydraulic and fuel systems of both commercial aircraft and military platforms. These hoses are designed to handle high pressures and extreme temperatures, which are typical in flight operations.

Hydraulic hoses with stainless steel braiding are essential for actuating systems like landing gear, brakes, and flight control surfaces. In fuel systems, they ensure secure and leak-free delivery of jet fuel. The braided steel layer adds a level of reinforcement that minimizes the risk of hose deformation or rupture during pressure spikes or intense vibration.

Additionally, the braided hose assemblies comply with stringent aerospace standards such as AS1946 and AS1339, ensuring they meet industry-specific tolerances and material requirements.

2. Automotive Performance and Racing Applications

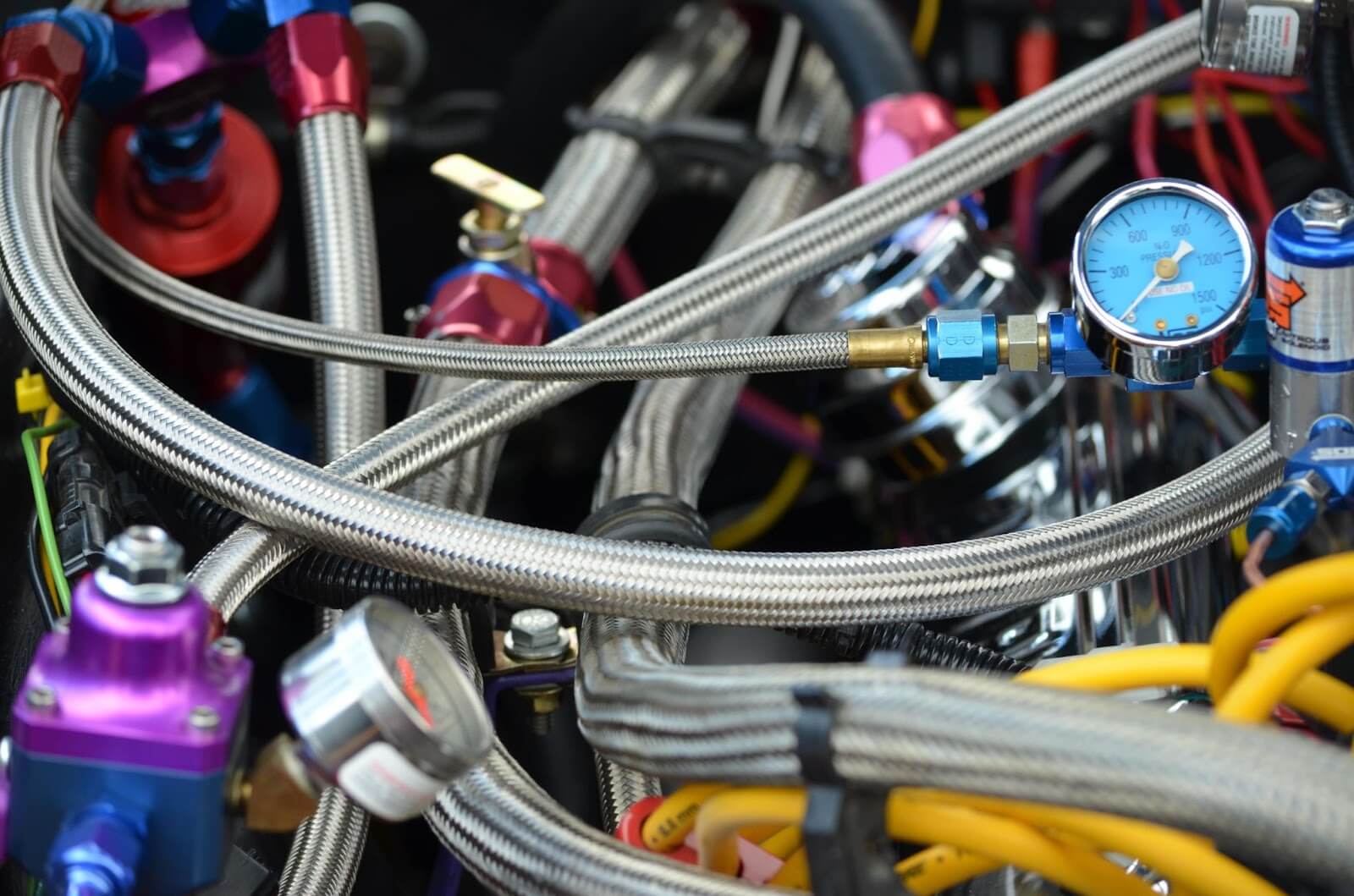

In high-performance and motorsport applications, standard rubber hoses can fail under the elevated pressures and temperatures of competitive environments. Steel braided hoses are widely used for oil lines, brake lines, clutch systems, and fuel delivery.

For example, brake lines with braided steel reinforcement provide a firmer pedal feel and improved responsiveness. This is because the braided layer reduces expansion under pressure, allowing for more precise control. Similarly, oil and fuel lines remain secure and functional under high engine heat and vibration.

Beyond function, the visual appeal of steel braided lines also adds to their popularity in custom vehicle builds.

3. Marine and Shipboard Systems

Marine environments expose materials to salt, moisture, vibration, and constant movement. Steel braided hoses are commonly used in marine applications due to their corrosion-resistant properties and mechanical strength.

They are used for bilge pump systems, water intake and exhaust lines, fuel lines, and hydraulic steering systems. Stainless steel braid protects the hose core from external wear, while also allowing some flexibility for easy routing in tight shipboard compartments.

Furthermore, steel braided hoses meet maritime safety certifications and reduce the risk of failures that could lead to onboard hazards.

4. Industrial Equipment and Manufacturing

In industrial settings such as manufacturing plants, chemical refineries, and food processing facilities, steel braided hoses are chosen for their durability and chemical resistance. These hoses are employed in pneumatic and hydraulic systems, chemical transfer lines, steam transport, and more.

For high-temperature applications like steam, the braided design ensures the hose maintains its integrity without kinking or blistering. For chemical handling, PTFE-lined braided hoses are often used to prevent contamination and corrosion from reactive fluids.

Because many factories operate 24/7, reliability is key. A failed hose can mean unscheduled downtime and high repair costs. That is why maintenance teams prioritize braided hose assemblies for mission-critical systems.

5. HVAC and Refrigeration Systems

Steel braided hoses are used in HVAC systems for connecting compressors, condensers, evaporators, and other components that experience pressure fluctuations. These hoses help absorb vibration and reduce mechanical stress on fittings and joints.

In refrigeration systems, especially those using high-pressure refrigerants, steel braided lines allow for secure fluid transfer while also meeting safety codes for pressurized equipment.

Moreover, their ability to handle rapid temperature shifts and resistance to UV and chemical degradation makes them ideal for rooftop HVAC installations or mobile units like refrigerated trucks.

6. Medical and Laboratory Equipment

In the medical and biotechnology sectors, precision and hygiene are paramount. Braided hoses are used in systems that require sterile fluid handling or gas transfer. For instance, surgical tools, autoclaves, and diagnostic machines often use PTFE-core braided hoses to maintain purity while ensuring flexibility and pressure resistance.

Laboratory setups may use these hoses for connecting gas cylinders or transporting chemicals. Because stainless steel does not corrode or leach, it is ideal for sensitive applications involving pharmaceutical or chemical reactions.

Hose assemblies in this sector are often manufactured under strict cleanroom conditions and tested to meet FDA or ISO standards.

7. Construction and Heavy Machinery

Steel braided hoses are a staple in construction equipment, such as excavators, bulldozers, and cranes. These machines rely on hydraulic systems to power heavy lifting, digging, and moving operations.

The hydraulic circuits in such equipment operate under high pressures and must withstand constant movement, environmental exposure, and occasional mechanical impact. Braided hoses provide the resilience needed to ensure hydraulic oil remains contained and flows efficiently, even in rugged work conditions.

From boom lifts to jackhammers, the construction sector benefits from the performance, reliability, and longevity of steel braided hoses.

Conclusion

Steel braided hoses are a versatile solution for fluid and gas transfer in demanding environments. From aerospace to automotive, and from marine to medical sectors, they offer the right blend of strength, flexibility, and resistance to harsh conditions. Their robust construction helps ensure system reliability, reduce downtime, and improve safety.

Understanding the specific needs of your application is key to selecting the right hose. Whether it’s a high-pressure hydraulic line in an aircraft or a chemical transfer tube in a lab, braided hose assemblies continue to be a trusted component across modern industries.

FAQs

What is a steel braided hose made of?

A steel braided hose typically includes an inner core of rubber, PTFE, or other flexible material, reinforced with one or more layers of stainless steel wire braiding.

Why is a braided hose better than a regular hose?

The braided structure provides additional strength, resists pressure expansion, and offers improved abrasion and chemical resistance compared to regular hoses.

Are steel braided hoses flexible?

Yes, despite the steel reinforcement, they retain significant flexibility, making them suitable for tight spaces or dynamic applications.

How long do steel braided hoses last?

Their lifespan depends on the environment and usage, but they often last significantly longer than standard hoses, especially in high-pressure or high-heat situations.

Hydrasearch

Hydrasearch

Your Mission is Our Commitment

Your Mission is Our Commitment