In the aerospace industry, selecting the right components for fluid conveyance is critical. Whether it’s for hydraulic systems, fuel delivery, or air pressure control, engineers must understand the difference between hoses and tubing. While they both carry fluids or gases, they are designed for very different applications.

This blog breaks down the key differences between hoses and tupes in a simple and clear way. It also explains why these differences matter in high-stakes environments like aircraft and defense systems.

What is a tubing?

A tubing is a rigid, hollow cylinder used to transport fluids or gases. Tupes are designed to maintain a fixed shape and are usually made from metals like stainless steel, titanium, or aluminum. They are commonly used when the routing path is straight or has fixed bends created by elbows or tees.

In aerospace, tubing are often used in fuel lines, structural hydraulic systems, and pressurized gas lines. Their strength and fixed dimensions make them suitable for areas with high mechanical stress.

Key Features of tubing:

- Fixed shape

- High-pressure resistance

- Requires fittings and welding for direction changes

- Long-lasting and durable under harsh conditions

What Is a Hose?

A hose is a flexible tube designed to carry fluids or gases between components. It is typically made of reinforced rubber, thermoplastic, or PTFE, often with braided metal or textile layers for strength. The key benefit of a hose is its ability to flex and move with the system.

In aerospace applications, hoses are used where movement, vibration, or thermal expansion is expected. For example, they are found in aircraft landing gear systems, engine connections, and vibration-prone zones.

Key Features of Hoses:

- Flexible and lightweight

- Easy to install and replace

- Absorbs vibration and thermal expansion

- Limited in pressure and temperature ranges compared to tubes.

Material Differences

Tubes are generally made of rigid metals, which offer excellent pressure containment and structural stability. Hoses, on the other hand, are made from composite materials. These include layers of elastomer, plastic, or PTFE along with braiding materials like stainless steel or Kevlar for extra strength.

In aerospace systems, the choice of material is based on the operating temperature, pressure, chemical compatibility, and required service life.

Installation and Maintenance

Installing tubes in an aircraft structure requires precision. Bending, welding, and securing are often involved, and any error can lead to performance issues or leaks. Once installed, tupes are difficult to modify or reroute.

Hoses are easier to install, especially in tight or moving spaces. Their flexibility allows quick replacements and adjustments. However, they tend to have a shorter lifespan and must be inspected more frequently for wear or leaks.

Pressure and Temperature Handling

Tubes are known for their ability to withstand high pressures and temperatures. In aerospace environments, where performance is non-negotiable, this makes tupes ideal for main hydraulic systems and fuel transport.

Hoses can also handle high pressures, but generally not as much as tubes. High-quality aerospace hoses can be used in demanding environments, but they must be selected carefully based on the specific application and stress factors.

Aerospace-Specific Considerations

In aerospace engineering, weight is a critical factor. Tubes, while strong, can be heavier than hoses. Designers often use hoses in areas where weight savings are necessary and flexibility is important.

However, safety regulations and certifications also come into play. Tubes are often preferred in mission-critical systems where failure is not an option. Hoses are more suitable for less critical functions or where system movement cannot be avoided.

Hose vs Tubes Comparison

| Feature | Hose | Tubes |

| Structure | Flexible, bendable | Rigid, fixed shape |

| Material | Rubber, PTFE, thermoplastics + reinforcement | Metals (stainless steel, aluminum, titanium) |

| Flexibility | High – suitable for movement and vibration | Low – used in fixed routing paths |

| Pressure Resistance | Moderate to High (depends on layers) | Very High |

| Temperature Handling | Moderate to High (application-specific) | Excellent – ideal for high-temp systems |

| Weight | Lightweight | Heavier |

| Installation | Easy – quick fit and replace | Requires precise bending and welding |

| Service Life | Shorter – more frequent inspections | Longer – durable under harsh conditions |

| Cost | Usually lower upfront | Higher material and installation cost |

| Typical Aerospace Uses | Engine vibration zones, movable parts | Main fuel lines, structural hydraulics |

Summary: Tubes vs Hose in Aerospace

While both hoses and Tubes are essential in aerospace systems, their uses do not overlap much. Tubes are rigid, strong, and ideal for high-pressure, high-temperature environments with fixed routing. Hoses are flexible, lightweight, and better suited for dynamic areas where movement or vibration occurs.

The choice between the two depends on system design, weight requirements, pressure levels, and flexibility needs.

Final Thoughts

Understanding the difference between a hose and a Tube is not just about shape or material. In aerospace applications, this choice can affect the entire system’s performance, safety, and reliability.

At Hydrasearch, we specialize in high-performance hose assemblies and aerospace fittings built for extreme conditions. If you’re looking for premium components for defense and aerospace projects, explore our product categories:

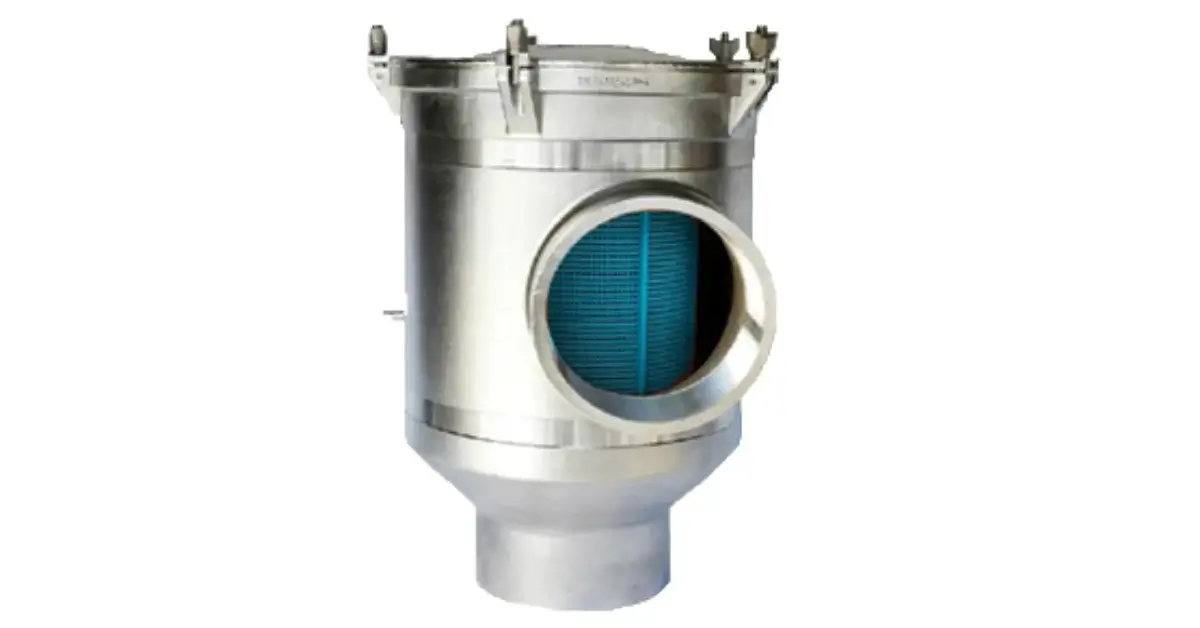

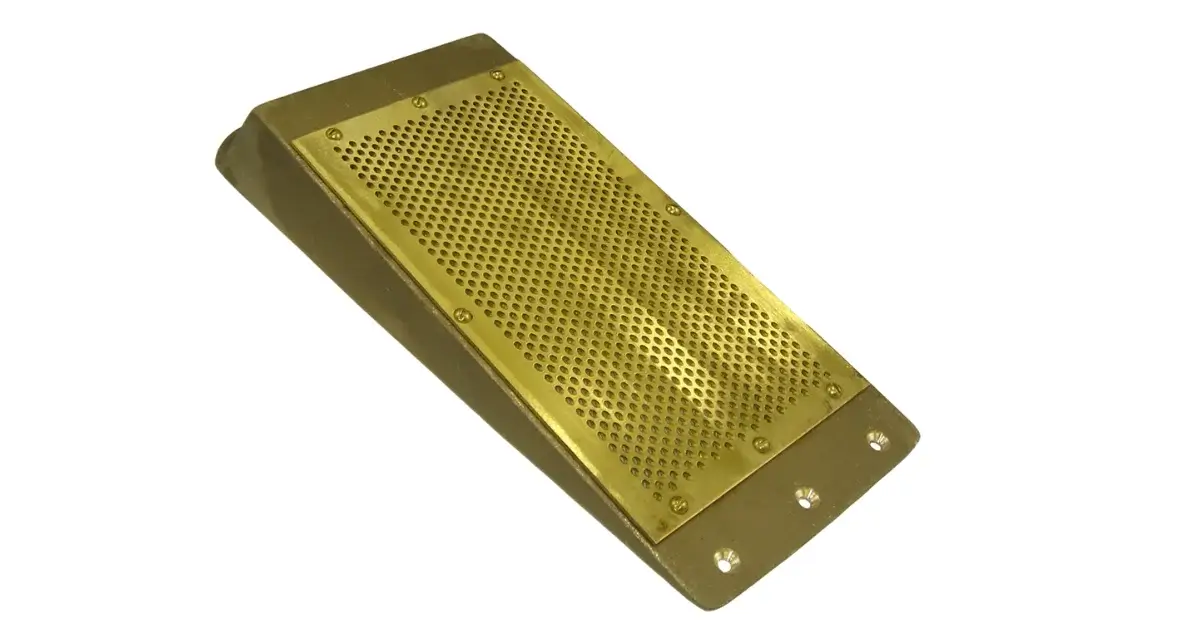

Hydrasearch

Hydrasearch

Your Mission is Our Commitment

Your Mission is Our Commitment